心肌梗死cro Plastic Injection Molding and Micron Tolerance Molding

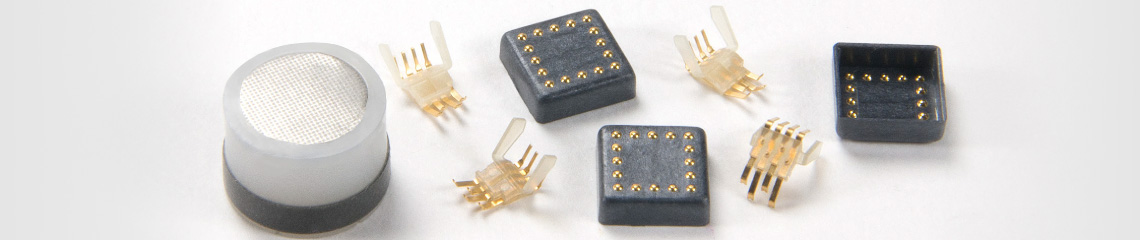

As one of the industry’s best injection molding manufacturers, we are a leader in the process of precision injection molding and micro molding. Our goal is to reduce your time to market and provide lowest-total-cost solutions to your most demanding molding programs. International companies rely on our experience and our focus on quality for problem-free production and superior value. Whether you’re in the market for microfluidics devices, medical device molding, or optical components, micro and micron tolerance molding is our specialty.

医疗和外科成型

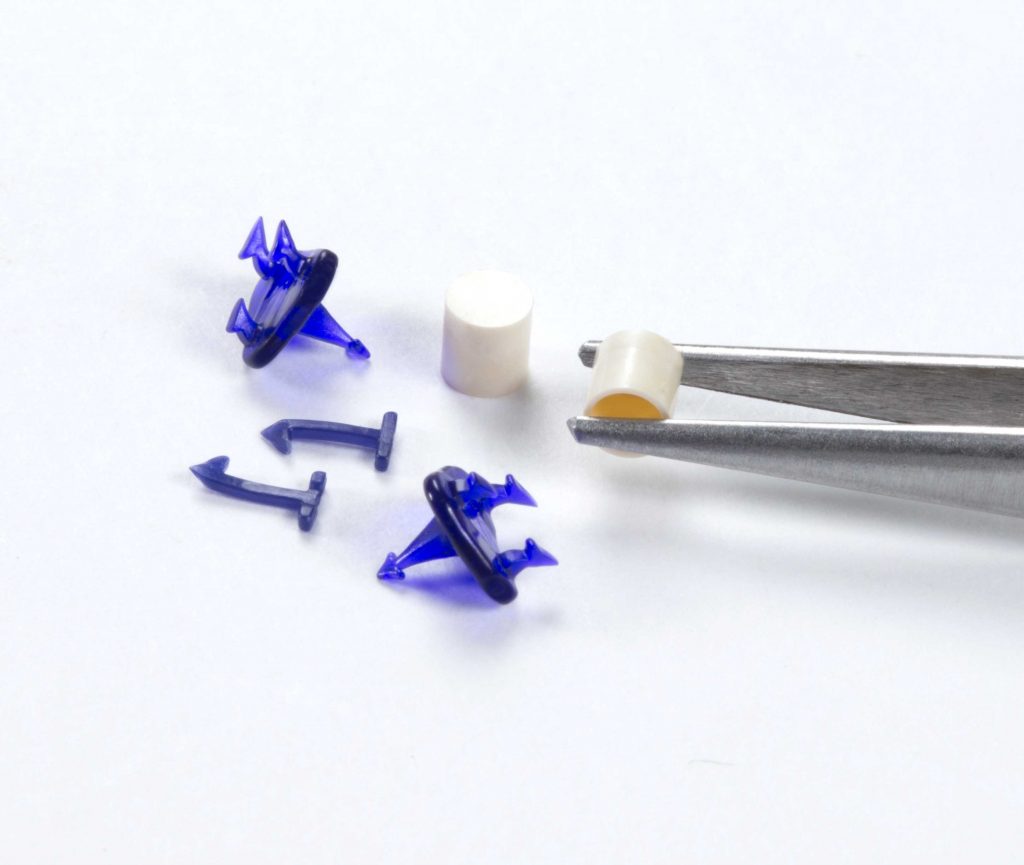

We have long-standing experience across a variety of medical molding applications requiring tight tolerances, insert molding, micro molding, micro insert molding, lab slides, luer connectors, sealing surfaces, and assembly work – or a combination of these needs. We offer:

- Class 100,000 cleanroom micro molding

- Features as small as 2 microns

- Part weights as low as .0001 grams

- Repeatability of +/- 2 to 4 microns (.002mm – .004mm)

Whether your products require high temperature engineered thermoplastics, thermoplastic elastomers, bio-resorbable or commodity resins, we can assist you. Among others, we manufacture components for surgical instruments, bioresorbable implants, drug delivery devices, dental implants, tracheotomy tubes and catheter components in our cleanroom.

联系